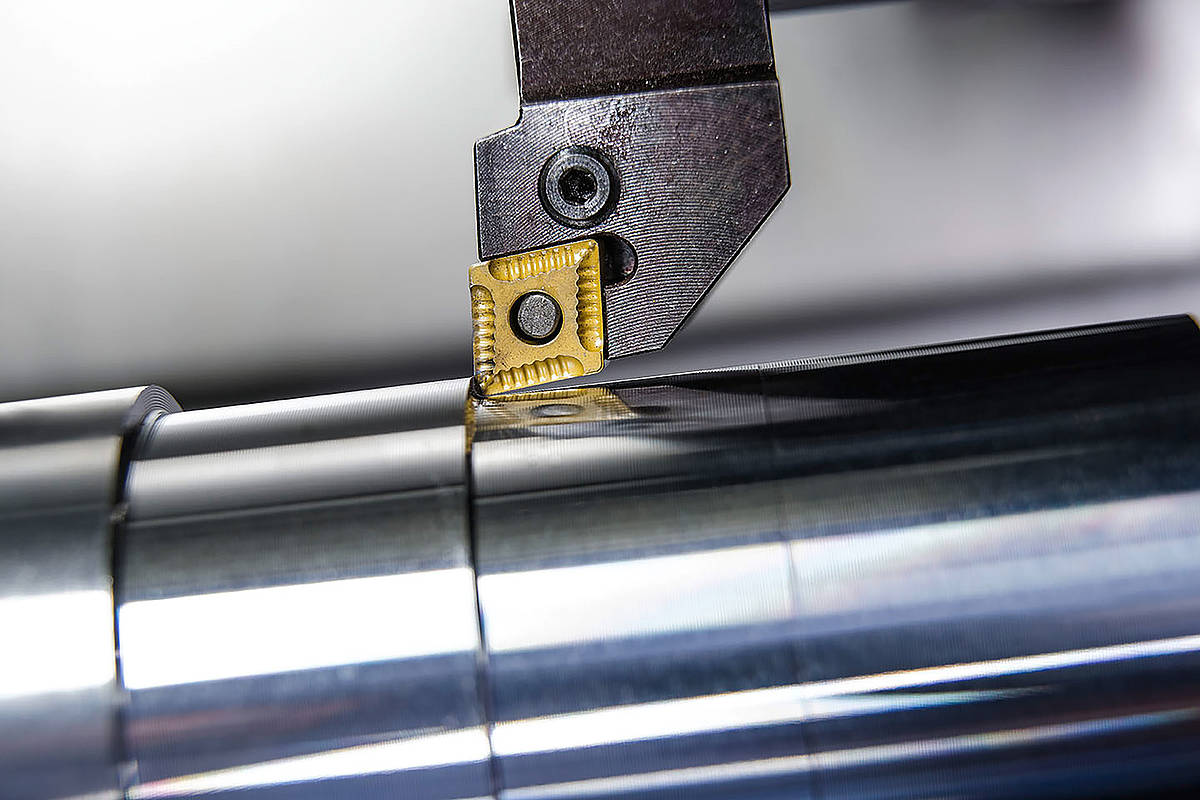

ISO Turning -

Cost reduction through

modern geometries

The ISO turning range with innovative cutting grades and modern geometries turns our customers’ cost spiral downward. Boehlerit offers the optimum indexable inserts for every turning application, e.g. for steel, cast and aluminium machining and the cutting of super alloys with difficult chip formation. Customer-specific solutions complete the wide range of ISO turning solutions.

S-Tool holder for internal machining with coolant

The new S-Tool holder for internal machining with internal coolant have an optimised chip channel and a modified WF dimension that enables smaller minimum drilling diameters. With diameters of 8, 10, 12, 16, 20 and 25 mm, a wide range of options are available for different applications.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Highest productivity with the smallest drill holes

The new Microtec tools for internal machining with additional holder are an innovative solution for turning small and narrow bores. The new Microtec tools consist of two parts: the clamping body and the drill shank. The clamping body is permanently mounted in the machine and has a holder for the drill shank. The boring bar can be replaced without removing the entire holder, making it easier and quicker to change the indexable insert. The five available boring bars are available for different drilling diameters and cutting edge angles and can be used with the existing CCGT030102, DCGT and VCGT minitools.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

A-8605 Kapfenberg

Austria

High performance, highest economic efficiency

Innovations in the field of carbide, coating as well as chip flow enable the development of a completely new grade generation for the steel turning process. The perfect coordination of these parameters leads to the new, economical steel turning grades BCP10T, BCP15T, BCP20T and BCP25T. The new Boehlerit steel grades offer excellent performance and machining reliability throughout the turning process.

The new BCP10T and BCP15T grades are recommended for medium applications at high cutting speeds, long engagement times and stable roughing applications, while the BCP20T and BCP25T grades achieve excellent results at medium cutting speeds.

The new turning grades are the ideal solution for the increasing challenges in the entire process of steel turning. With maximum economic efficiency, Boehlerit is the ideal, innovative partner.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Steeltec LCP15T

Efficiency increase in steel machining by no less than a third

…with the new Boehlerit cutting inserts Steeltec LCP15T, brand new turning grades and geometries for steel turning applications that are designed for a straight, uninterrupted cut.

An innovative, harder gradient hard metal ensures extra-high safety while the MT-CVD carbide layer is more resistant to wear and tear and ensures higher cutting speeds, in particular through an increase in the share of the TiCN layer. At the same time, Boehlerit has replaced HV2700Kappa Al2O3 (HV2350) with the more wear-resistant Alpha Al2O3 and increased layer thickness by 25%. “The higher the process temperature, the greater the level of isolation”, explains Heinz Gaber from Boehlerit Product Management in Kapfenberg, Austria.

FP = Fine ISO P, for the fine turning of steel with straight cuts.

FMP = Fine Medium ISO P, for fine and medium intermediate geometries.

MP = Medium ISO P, for medium steel machining.

MRP = Medium Roughing ISO P, for roughing intermediate geometries.

RP = Roughing ISO P, as a variant for heavy roughing.

BC / BCU = Boehlerit Copy Universal, for copying geometries with good chip-breaking properties. It is considered a real problem solver for steel and super alloys

In addition to harder metal and increased layer thickness, the new geometries that were developed in the chip channel also increase efficiency considerably. Using a high-speed camera, the breaking of the chip was analysed meticulously for each turning application to determine the optimum chip flow. The result – optimum turning geometries for highly diverse turning applications.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Steeltec LCP25T

Universal steel machining at top level

Striving for more universality, longer service life, more machining reliability and reliable chip breaking when turning steel, Boehlerit uses many of its patented innovations in its latest innovative cutting material. The new gradient carbide for the universal LCP25T universal turning grade (ISO application range P25) that was presented at EMO Hanover 2013 ensures a high degree of machining reliability on an extremely wide range of steel materials. The patented Nanolock TiCN bonding layer safely bonds the significantly harder Alpha-Al2O3 (with better insulating properties) to the patented Yellow-Al2O3 layer. This innovative cutting material with an extremely thick carbide layer in combination with the geometries that have been developed in the Boehlerit chip channel, increases the service life by 60% ensuring the highest degree of universality in steel machining. The new, universal LCP25T turning grade has been developed especially with small and medium-sized companies in mind, customers who are often faced with new challenges when it comes to steel components and ensuring economic efficiency of turning operations. Boehlerit is the ideal, innovative partner for such tasks. Its outstanding achievements earned the company a particular distinction: A Boehlerit patent was elected among the top 10 of 3,300 Austrian patents registered in 2012.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Supertec LC415Z

Optimum treatment of super-alloys difficult to machine

The Supertec LC415Z turning grade with its micro-grain substrate ensures sharp micro-geometry and edge stability at the same time. The high-temperature resistant and extremely smooth supernitride coating ensures high cutting speeds and extended tool life for super-alloys such as Inconel, Hastelloy, Nimonic and for titanium alloys. Supertec LC415Z also ensures higher economic efficiency on austenitic, stainless steel at higher cutting speeds (> 200 m/min).

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

FN geometry determines the processing pace

The newly designed FN geometry perfectly complements the existing range thanks to its unique chip former that reaches far into the corner radius, thereby achieving a chip break even with smaller feed depths. Depending on the machining process, there are two grades available: The BCN10T (HC-N10) grade is ideal for the processing of alloyed aluminium materials and NF metals. Thanks to its PVD TiAlN layer, it is also suitable for stainless steels and grey cast iron. The BWN10T (HW-N10) milling grade, on the other hand, is best suited for the machining of low-alloy aluminium and NF metals with medium to high cutting speeds.

Alutec

BAL aluminium range

The Alutec range excels with the most advanced cutting materials and associated chip breakers. With LW610, LW612 and LC610T, Boehlerit has a very wide range of solutions for aluminium machining at hand.

Applications range from turning, parting and milling to the most universal Pentatec turning-drilling tool. Five machining operations can be carried out with this combination tool. Chip breakers such as BAL (Boehlerit Aluminium), ALM (aluminium for milling) or GF (Grooving Fine) are outstanding for their optimum chip flow.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Titanium grade BCS10T and super alloy

grade BCS20T for successful machining of super alloys

The leading hard metal experts from Boehlerit, Austria, have developed a special carbide grade for the machining of titanium; the tendency for plastic deformation of this grade is small which makes it the perfect choice for titanium that is extremely difficult to machine. The grade ensures a high degree of machining reliability on materials such as Ti – 6Al – 4V or Ti – Al – Sn. Thanks to the innovative, oxidation-resistant plasma CVD TiBN layer of the BCS10T turning grade, cutting speed is increased by 40 % while the service life is extended at the same time.

Boehlerit takes up the challenge of machining all materials that place the most exacting demands on the cutting material. The new turning grade BCS20T with an exceptionally fine-grained carbide substrate and a PVD layer enriched with aluminium has been developed for super alloys such as Inconel, Hastelloy and Waspaloyy. The layer reduces the adhesive bonding tendency, ensures high temperature resistance and extends the service life by up to 30% to 50%. Both the BCS10T turning grade for titanium machining and the BCS20T grade for super alloys are available with the MT chip former ("Mittel Titan") in the most common ISO indexable inserts for medium and light roughing.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Performance where it really matters

With its latest indexable insert geometry MRM, Boehlerit has added yet another innovation to its ISO turning programme for the medium to rough machining of stainless materials, setting new standards in the process and making optimised indexable inserts available for a wide range of applications using stainless steels.

The new MRM chip breaker complements the BMRS geometry, which is well established on the market and covers a similar feed rate range but differs in terms of micro geometry due to the deeper chipping angle. In this way, the cutting forces are reduced, resulting in increased process safety and a prolonged lifespan on stainless steels with high hardness levels.

With the new MRM geometry for medium roughing on stainless steels, the carbide and tool specialists from Kapfenberg have launched the perfect addition to its already comprehensive ISO turning programme. Users who want to keep an eye on costs for their roughing operations and are looking for a cost-effective solution will make the right choice with the Boehlerit MRM geometry.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

BCK10T and BCK20T

The revolution in cast iron turning

Austrian carbide and tool specialist Boehlerit has optimised the successful TERAspeed 2.0 coating for use in cast iron milling and now cast iron turning applications are also set to benefit. A thorough analysis of the market situation and coating tests that were completed internally paved the way for a new generation of coatings. The new cast CVD coating makes the most of the advantages of its individual components. Alpha-aluminium oxide is separated by means of targeted process management. It works as a heat shield and protects the indexable insert from high temperatures. Underneath, a medium-temperature titanium-carbon nitride layer provides the required wear resistance. A thickness of 20µm and the optimised roundings of the edges ensure a high level of edge stability and ideal cutting conditions. The current geometries of the casting programme are made with the latest generation of reference clamping systems. Compared to older systems, the increased rigidity and repetition accuracy makes for a reduction of the pressing gap, which in turn increases press quality (burr-free pressing). This has a positive influence on work flows further down the line and significantly improves productivity.

The new Boehlerit casting grades BCK10T and BCK20T offer top quality, excellent machining properties and optimal distribution of cutting forces.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Quattrotec

Intelligent turning-drilling applications now extended

With the introduction of the new Quattrotec tool system, Austrian carbide and tool specialist Boehlerit makes it possible for users to drive down costs further, in an even broader material range. Thanks to the special design of the base body, four machining operations – drilling into solid material (including off-centre drilling), inside turning, face cutting and longitudinal turning – may be performed with low vibrations and just a single tool. The EasySafe system is the uncontested highlight of the Quattrotec: A notch on the underside of the indexable insert ensures that it can be fitted into the seat speedily and 100% correctly. Easy to install, safe to use!

In a tried-and-tested, highly diverse range of grades, Boehlerit combines substrates of different levels of hardness, with either a wear-resistant CVD coating or a universal, process-safe PVD coating. The Kapfenberg-based tool specialist uses different carbide substrates that are coordinated in such a way as to achieve optimised machining properties. The market launch already saw no less than six directly pressed grades, and two more ground varieties for non-ferrous metals were added. The existing Quattrotec program with diameters of 10, 12, 16 and 20 mm was also expanded by two additional diameters, 18 and 25 mm. In addition, indexable inserts for aluminum machining were added to the program for all six tool sizes.

The innovative Quattrotec tool programme reduces machining and tool changing times, saves tool places and makes it possible to drill flat-bottomed blind holes. At the same time, this highly stable tool system that was developed from scratch also offers improved process safety and increases efficiency and flexibility during application.

Quattrotec – explore new paths with Boehlerit!

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Pentatec

The universal turning-drilling tool

substitutes up to five ISO tools and reduces machining times by up to 30%, as no tool-changes are needed and empty tool cycles avoided.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Grooving

Systemised parting and turning. Easytec combines a wide range of applications with ease of handling.

Easytec makes reliable and safe grooving and parting of shafts, rods and pipes possible. It comes with single- or double-edged parting inserts that go into the same tool holder. This means shorter set-up times and reduced tool magazine occupancy.

The economic advantage becomes even more apparent when Easytec is used for longitudinal turning, face turning, copy turning or parting and grooving. The edge works all the time – especially when turning grooves and pockets on the outside, insider or on the face –while the other tools are often idle (with up to 50% empty runs). In longitudinal turning, where the wiper effect of the wide face is brought to bear, new standards are set in terms of surface quality – Easytec can in some cases even make up for grinding operations.

A wide range of chip forming equipment for parting (GM, GF, RU, UM) and parting and grooving (TM and TA) plus four carbide grades, one ceramic and one PKD grade ensure controlled chip evacuation and a highly economic tool service life.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria