Know-how

from the machining

of tubes

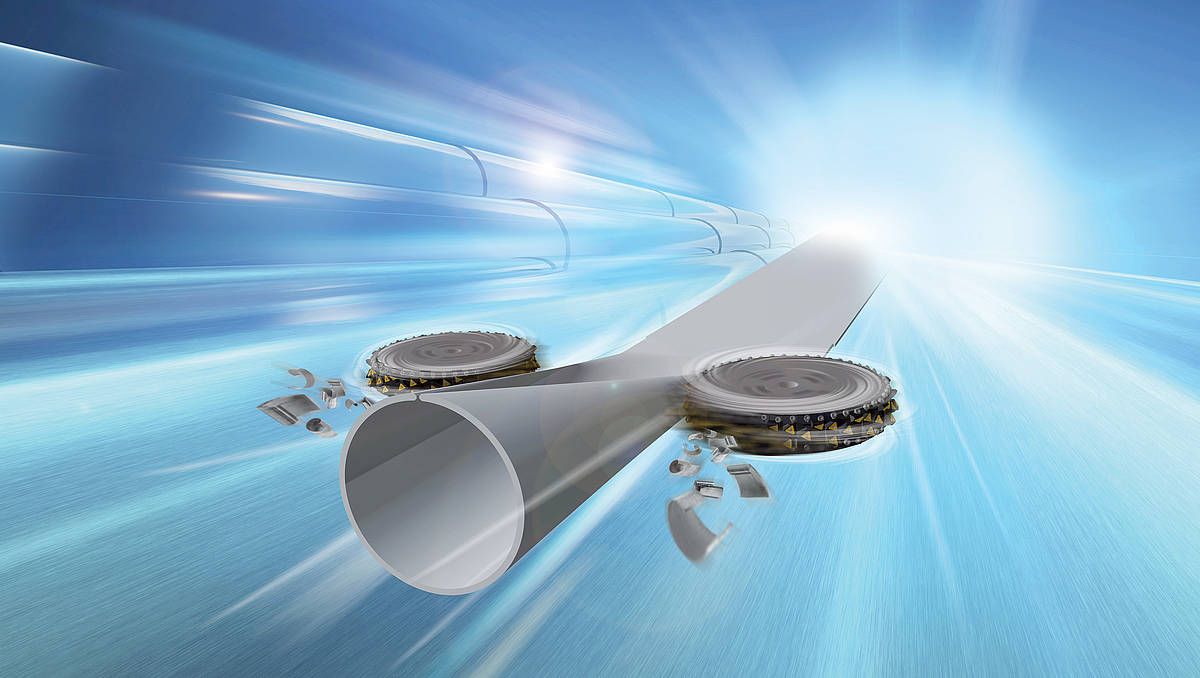

Boehlerit offers an unrivalled diversity of products and the full range of cutting and machining solutions for the production of large-diameter pipes. In addition to various components for pipe-end machining, the standard processes of plate edge machining are also used in other lines of industry.

The longitudinal- and circular weld seam millling tools from Boehlerit guarantee maximum precision and tool life in addition to maximum performance

A very essential part of the weld seam preparation of offshore wind towers is the right milling tool. Here, Boehlerit meets the challenges placed on the products due to the enormous workpiece dimensions. And these lie, among other things, in the tool life of the milling tools, which in the specific application reach diameters of between 950 and 1,100 mm. For optimal preparation of the weld seam, it has to be milled in several passes to a depth of two thirds of the material thickness. The lengths to be machined are therefore very large, but a constant tool change would be to the detriment of productivity and ultimately economic efficiency. Boehlerit offers decisive advantages here, because the inserts, which are specially designed for the required geometries, impress with maximum performance and long tool life, even with materials that are difficult to machine." In addition, high feed rates are possible.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

A fresh take on inside deburring

Welded pipes with a longitudinal seam are frequently used for complex applications in different industries, for instance, the automotive or petroleum industry. To fulfil the complex requirements with regard to tensile strength and dimensional tolerance, the welding burr is often removed at the pipe production stage. The new Boehlerit internal scraper rings constitute the perfect solution for the clean and efficient deburring of welded pipes.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Weld edge processing

The first machining step in the sequence of processing steps in large-diameter pipe production is the preparation of the plate edges or "welding seam machining" as it is known by the experts. This process step is normally done by milling; the edges are machined in synchronous mode with milling heads positioned opposite to each other. These tools are designed and tailor-made for the respective systems and the materials to be machined, and for the material thickness and edge profiles required. In addition to conventional monobloc tools, Boehlerit also offers modular profiled cutting heads for this purpose. These consist of a basic body with exchangeable milling cartridge and indexable inserts. With the appropriate milling cartridges and indexable inserts Boehlerit is able to provide all edge profiles that are customary in the industry, i.e. users can choose between I-profile, X-profile, Y-profile or tulip-profile. One advantage of modular standard components is the fact that the entire tool does not need to be replaced in the event of damage, but only the cartridges concerned. The cutting profile can also be quickly and easily changed if needed by replacing the cartridges.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Sheet edge preparation

When the plates have been bent to form pipes and when welding has been completed, the next machining step is that of deburring the welding seam from the inside and/or outside. This process is similar to planing; the pipe is moved along the stationary tool. Boehlerit offers the necessary tool holders, cartridges and cutting inserts and/or rings for this process.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Pipe end bevelling

At the end of pipe production, the pipe ends are chamfered. This is, again, a preparation for welding with the respective requirements for precision. The process is done by turning. Boehlerit provides the complete tool systems including face plate, spring-borne tool carriage, cartridge holders, copying roller and various spindles.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria

Oilfield technology

Boehlerit offers ideal solutions for your application in the field of API threading. Whether face turning, chamfering, copying, roughing or peeling - nearly all machining solutions can be covered.

Boehlerit GmbH & Co.KG

Segment Cutting Tools

Werk VI-Straße 100

8605 Kapfenberg

Austria