Carbide as construction material

Recent years have seen a marked increase in the use of carbides as construction components. The demand for a material that offers the highest possible level of reliability in highly diverse conditions comes from a wide range of industries, such as the chemical industry, plastics manufacturing, the food industry, oil and gas production, beam technology, the recycling industry and also the health and hygiene sector. One of the most sought-after characteristics of carbide is that it offers an outstanding level of safety and reliability, unrivalled by any other known material. Reliability is related to uncontrolled wear – and wear resistance is the most important characteristic of carbide. Where materials are also exposed to impact stress, high loads and/or pressure, high temperatures and/or corrosion, carbide is often the last one standing when it comes to dealing with all these factors. The use of carbide makes sense in the following scenarios:

• High quantity

• High demands in terms of quality consistency of the manufactured products

• Cost-effective production

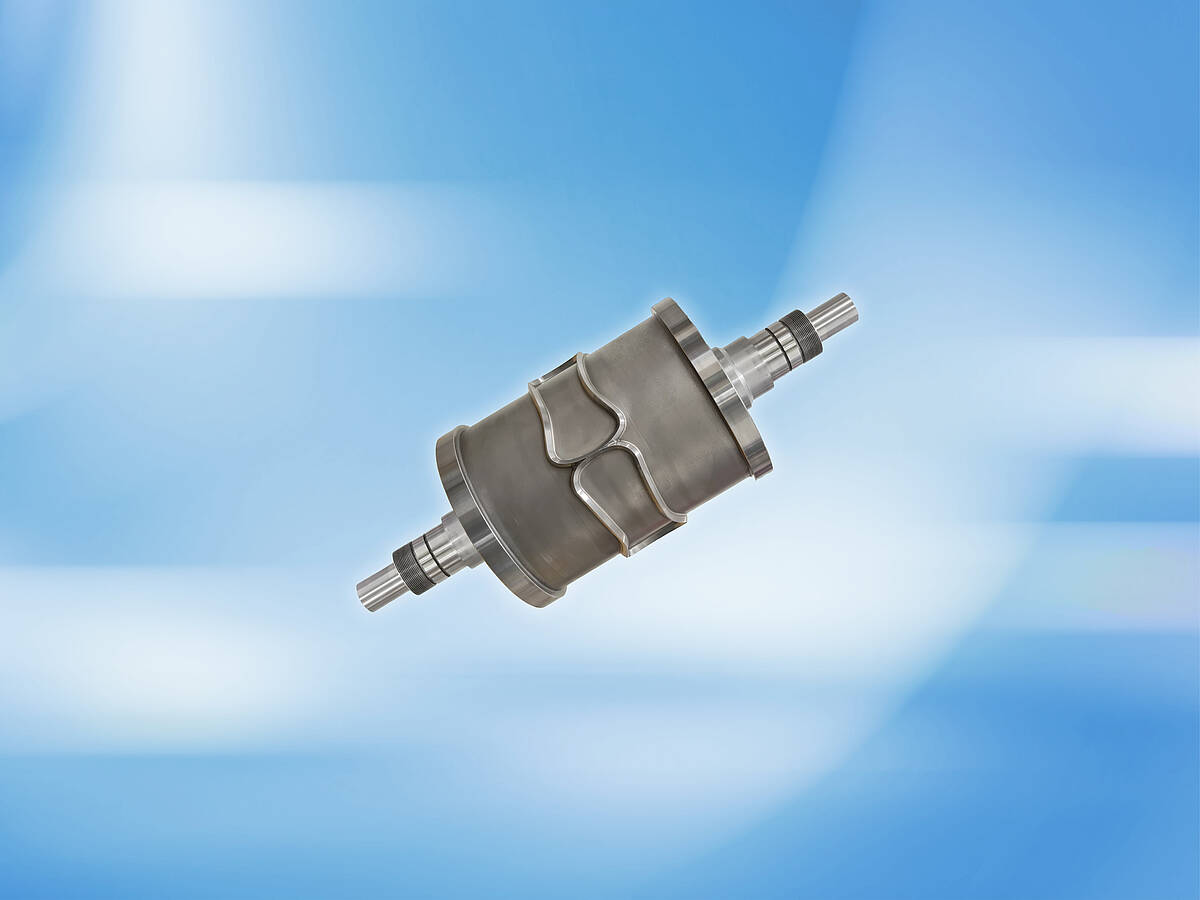

As a rule, these factors apply to high-volume production scenarios, where resistance to abrasive and surface-damaging stress is key and materials have to withstand a high level of mechanical stress. Tools can be made from solid carbide or a compound of carbide and steel. The steel/carbide compound can be created by soldering, gluing or mechanical means of fastening. Experience has shown that the best construction solutions usually result from a close cooperation between applications engineers and carbide manufacturing engineers. It is highly advantageous to set up these contacts at an early stage of a given project, when it is still possible to adjust construction in such a way that it fully leverages the benefits of carbide.

Boehlerit GmbH & Co.KG

Segment Wear protection & semi-finished products

Werk VI-Straße 100

8605 Kapfenberg

Austria